UV curing systems have revolutionized auto body care and repair industries by significantly reducing paint and coating dry times from hours or days to just minutes, leading to faster restoration processes, increased productivity, and lower operational costs. These systems, through ultraviolet light-initiated chemical reactions, also benefit manufacturing sectors such as printing, packaging, electronics assembly, and PCB production, offering precise, quick drying solutions that save businesses money while maintaining high product quality.

UV curing systems are transforming industrial processes, offering a game-changing approach that saves time and money. This innovative technology revolutionizes traditional drying methods by swiftly curing coatings, adhesives, and inks without requiring lengthy waiting periods. From manufacturing to construction, UV curing systems streamline production lines, reducing labor costs and minimizing material waste. Moreover, their superior durability ensures long-lasting, high-performance finishes, preventing costly rework and maintaining product quality over time.

- Speeding Up Production with UV Curing Systems

- – Time-saving benefits of UV curing compared to traditional drying methods

- – Examples of industries and applications where UV curing reduces production time

Speeding Up Production with UV Curing Systems

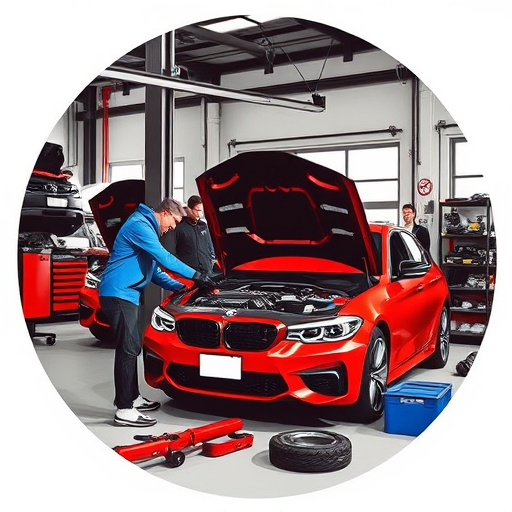

UV curing systems have revolutionized many industries, especially auto body care and repair. Traditional drying methods for paints and coatings can take hours or even days, significantly slowing down production in auto body shops. However, UV curing systems offer a game-changer solution by reducing dry times to just minutes, which is a significant time savings for busy car bodywork services and auto repair shops.

This rapid curing capability means that auto body restoration processes can be completed faster, increasing productivity and efficiency without compromising quality. Consequently, these advanced systems not only speed up production but also help reduce operational costs associated with extended waiting times.

– Time-saving benefits of UV curing compared to traditional drying methods

UV curing systems offer a significant advantage over traditional drying methods when it comes to time savings. In industries such as automotive and vehicle restoration, where speed and efficiency are paramount, UV curing stands out. With conventional drying techniques, materials can take hours or even days to set and cure completely, leading to lengthy production times. In contrast, UV curing systems can achieve full cure in just minutes, significantly reducing the overall turnaround time for processes like car bodywork repairs and restoration projects.

This rapid curing feature is attributed to the powerful ultraviolet light used in UV curing systems, which initiates a chemical reaction within the applied materials, setting them almost instantaneously. This time-saving benefit translates directly into cost savings for businesses and consumers alike, as faster production cycles mean higher throughput rates and reduced labor costs.

– Examples of industries and applications where UV curing reduces production time

UV curing systems have revolutionized various industries by significantly reducing production time and enhancing efficiency. In the automotive sector, for instance, UV curing is widely used in auto body shops and collision repair centers. The rapid curing properties of UV light allow for faster drying and hardening of paints, adhesives, and coatings. This not only speeds up the overall restoration process but also ensures a higher quality finish, as the reduced cure time minimizes the risk of smudges or imperfections.

Another notable application is in manufacturing, where UV curing systems play a pivotal role in industrial production lines. From printing and packaging to electronics assembly, these systems offer precise and quick drying solutions. For example, in the production of printed circuit boards (PCBs), UV curing can accelerate the hardening of photo-resist materials, enabling faster prototyping and reduced lead times. This efficiency translates into cost savings for businesses while maintaining high standards of product quality.

UV curing systems offer a significant advantage in terms of speed and efficiency, revolutionizing various industries. By eliminating the need for traditional drying methods, these systems significantly reduce production times, enabling faster turnaround and increased productivity. The benefits are clear: from manufacturing to printing, UV curing systems save time and money, making them an essential consideration for any business aiming to stay competitive in today’s fast-paced market.