UV curing systems, using ultraviolet light, revolutionize industrial processes by swiftly curing materials across diverse sectors like printing, coatings, adhesives, and collision damage repair. They significantly shorten drying times compared to traditional methods, offering paramount efficiency in vehicle body repair and scratch repair through precise UV exposure control. These systems have transformed automotive collision repair, reducing drying times for paints, adhesives, and coatings, ensuring quick turnarounds and critical advantages in high-demand workloads.

“Unleashing the power of light, UV curing systems have transformed various industries with their rapid and efficient drying and hardening processes. This article delves into the fundamentals of these innovative technologies. We’ll explore what UV curing systems are, how they harness ultraviolet light to cure materials, and their diverse applications across sectors. By the end, you’ll grasp the benefits that make these systems a game-changer in modern manufacturing.”

What are UV Curing Systems?

UV curing systems are advanced technologies that utilize ultraviolet (UV) light to swiftly and efficiently cure or harden various materials, particularly in industrial processes. This innovative approach has gained significant traction across diverse sectors, from printing and coatings to adhesives and even collision damage repair. By emitting UV radiation, these systems initiate a chemical reaction within the material, causing it to transform from a liquid or viscous state to a solid finish.

One of the notable advantages of UV curing systems is their ability to significantly reduce drying times compared to traditional methods. This is particularly beneficial in vehicle body repair and scratch repair processes, where speed and efficiency are paramount. The precise control over UV light exposure ensures optimal curing, minimizing the risk of surface imperfections or uneven hardening often associated with manual drying methods.

How Do UV Cures Work?

UV curing systems have revolutionized various industries, including automotive collision repair and vehicle restoration. The process behind their effectiveness is quite fascinating. When a UV light source, typically an LED or a mercury lamp, emits ultraviolet radiation, it interacts with specific chemicals present in the resin or coating material. This unique interaction triggers a chemical reaction that hardens and cures the material almost instantly.

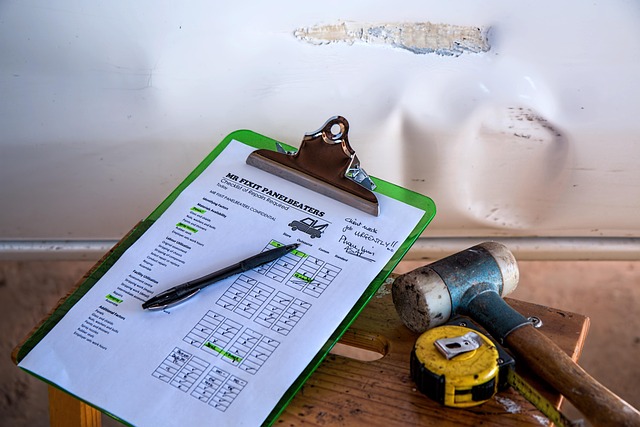

In automotive collision repair centers and vehicle customization workshops, UV curing systems are highly valued for their speed and precision. They ensure rapid drying and hardening of paints, adhesives, and coatings, reducing the time required for traditional curing methods. This efficiency is crucial in keeping up with the demand for quick turnarounds in these bustling environments where every minute counts.

Applications and Benefits of UV Curing

UV curing systems have transformed various industries by offering a swift and efficient method for hardening and drying materials. Their applications are diverse, from printing and coatings to adhesives and resin polymers. This technology has revolutionized car repair shops and luxury vehicle repair facilities, enabling faster turnaround times and improved quality in collision repair processes.

One of the key benefits of UV curing is its ability to reduce production time significantly compared to traditional drying methods. In a car repair shop setting, this means less downtime for vehicles, increased productivity, and ultimately, cost savings. Additionally, UV curing systems provide consistent and precise results, ensuring high-quality finishes in both automotive and other industrial applications.

UV curing systems have transformed various industries by offering swift, efficient, and eco-friendly solutions for material hardening and drying. By leveraging ultraviolet light, these systems provide a range of benefits, from improved production speeds to enhanced product quality and durability. As the demand for advanced coatings, adhesives, and printing technologies grows, understanding UV curing becomes essential for businesses aiming to stay competitive in today’s market.